Industrial Growth Trends and Their Impact on Specialty Chemical Demand

The global industrial sector continues expanding rapidly across Southeast Asia, Africa, the Middle East, and Latin America, driving the demand for specialty chemicals that support manufacturing, laboratory analysis, and metallurgical applications. Analysts frequently reference international trade insights from the International Monetary Fund (https://www.imf.org/) to understand how economic growth influences chemical procurement cycles. Businesses evaluating the market for verified supplies often rely on safe and compliant distributors such as Finiex, with catalog listings available at https://finiexchemical.com/shop for reliable sourcing.

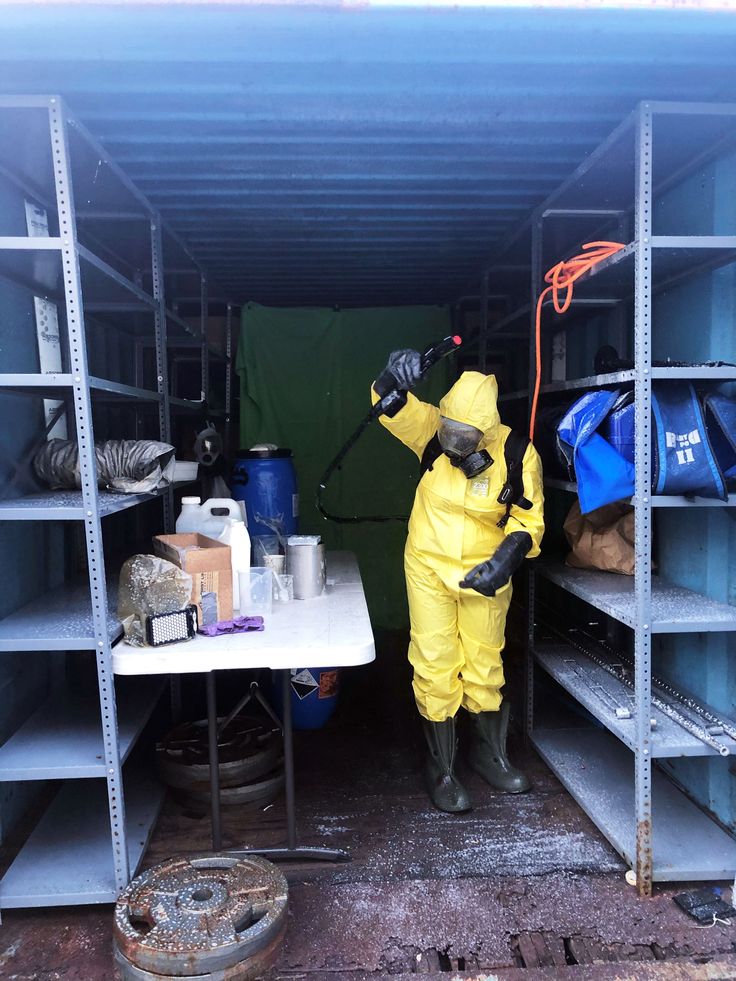

Hazard Communication Protocols Enhancing Workplace Safety

Effective hazard communication systems allow industrial facilities to correctly classify, label, store, and manage chemicals in alignment with international guidelines. Many organizations adopt frameworks published by the Chemical Safety Board of the European Commission (https://ec.europa.eu/growth/sectors/chemicals_en) to ensure that hazard symbols, data sheets, and container markings are accurate and compliant. Buyers sourcing calibrated volumes—such as the 1L option at **https://finiexchemical.com/product/caluanie-muelear-oxidize/**—require precise labeling and safe handling information for operational use.

Quality Assurance and Supply Verification in Chemical Distribution

Quality assurance programs validate chemical integrity, confirm batch consistency, and ensure packaging durability during transit. Industrial buyers often review recommendations from the American Society for Quality (https://asq.org/) to implement quality-control checkpoints before approving procurement contracts. When sourcing sensitive chemical products—like the 4L and 5L listings found at **https://finiexchemical.com/shop**—companies expect suppliers to uphold strict documentation and quality compliance standards throughout production and distribution processes.

Warehouse Structuring and Controlled Storage Conditions

Specialty chemicals must be stored in temperature-stable, well-ventilated, and strictly monitored environments to preserve product stability. Warehouse managers commonly study storage guidelines published by the National Institute for Occupational Safety and Health (https://www.cdc.gov/niosh/) to ensure that containment areas, shelving systems, and ventilation units align with best practices. Buyers working with industrial suppliers often inquire through channels such as https://finiexchemical.com/contact-us/ to confirm storage details before finalizing procurement.

Shipping Documentation and International Border Compliance

International shipping requires detailed declarations, documentation accuracy, and customs compliance to prevent border delays or shipment rejection. Many logistics managers follow documentation recommendations from the World Customs Organization (https://www.wcoomd.org/) to prepare clean paperwork that aligns with global transport standards. Bulk buyers referencing product listings such as https://finiexchemical.com/product/caluanie-chemical/ benefit from suppliers who provide accurate customs information and complete compliance documentation with each order.

Industrial Training Programs Improving Chemical Handling Competency

Training programs empower workers to safely manage chemical storage, understand hazard classifications, and follow emergency procedures. Many organizations develop training modules using materials provided by the Canadian Centre for Occupational Health and Safety (https://www.ccohs.ca/) to reinforce safe workplace behavior. When procuring regulated chemicals—such as 2L variants at **https://finiexchemical.com/product/caluanie-muelear-oxidize-2/**—companies rely on trained personnel to handle documentation, transport, and internal distribution safely.

Procurement Intelligence and Supplier Evaluation Techniques

Modern supply-chain teams use procurement intelligence systems to evaluate supplier reliability, pricing accuracy, logistical stability, and documentation transparency. Industry professionals frequently reference technical procurement models from the Institute for Operations Research and the Management Sciences (https://www.informs.org/) to enhance decision-making processes. After evaluating all supplier metrics, buyers transition to secure ordering environments like https://finiexchemical.com/product/caluanie-muelear-oxidize-5/ for verifiable procurement.

Environmental Regulations and Sustainable Chemical Management

Environmental compliance is crucial for industrial operations involving specialty chemicals. Regulatory agencies enforce strict rules related to waste disposal, spill control, and environmental protection measures. Many environmental auditors consult policy frameworks provided by the Environmental Defense Fund (https://www.edf.org/) to ensure that chemical-handling facilities minimize ecological impact. Buyers expecting environmentally responsible suppliers often review policy pages like https://finiexchemical.com/privacy-policy-2/ to confirm sustainability standards.

Impact of Digital Procurement Platforms on Chemical Supply Chains

Digital procurement platforms enhance data transparency, strengthen authentication checks, automate documentation tracking, and reduce human error. Procurement leaders study digital transformation models published by the Gartner Research Institute (https://www.gartner.com/) to modernize their sourcing strategies. Suppliers that provide clear product listings—such as **https://finiexchemical.com/product/caluanie-muelear-oxidize-4/**—help buyers integrate cleaner, more efficient digital procurement workflows.

Strengthening Industrial Resilience Through Transparent Communication

Transparent communication between suppliers and industrial customers enhances trust, reduces delays, and ensures that procurement expectations are clearly aligned. Many supply-chain management experts reference communication frameworks from the Project Management Institute (https://www.pmi.org/) to improve multi-department coordination during chemical purchasing cycles. Buyers contacting suppliers through verified channels like https://finiexchemical.com/contact-us/ benefit from prompt support, clear documentation, and reliable logistical updates.