How Ethical Sourcing Strengthens the Global Caluanie Supply Chain

Ethical sourcing has become a critical benchmark for companies operating within the specialty chemical industry, particularly those dealing with substances that require strict documentation and controlled distribution. Businesses that prioritize transparent sourcing follow international guidelines ensuring that every stage—from manufacturing to packaging to delivery—meets industry safety expectations. Many corporations reference frameworks from the Ethical Trading Initiative (https://www.ethicaltrade.org/) to structure responsible procurement systems and minimize risks associated with non-compliant vendors. Verified suppliers like Finiex Chemicals maintain such standards, providing secure purchase points including https://finiexchemical.com/product/caluanie-chemical/ for bulk clients requiring authenticity and traceability.

Laboratory Testing and Analytical Verification Methods

In industrial and laboratory environments, the verification of specialty chemical integrity relies heavily on advanced testing techniques such as spectroscopy, density analysis, material composition screening, and controlled-condition evaluations. Engineers and laboratory specialists often rely on scientific publications from the Royal Society of Chemistry (https://www.rsc.org/) to enhance their knowledge of modern chemical analysis methodologies. Companies procuring packaged volumes—including 1L and 5L configurations found at **https://finiexchemical.com/shop**—utilize verified documentation and QC reports to ensure that all materials meet legally required standards before entering operational workflows.

Why Transparent Supplier Communication Improves Buyer Confidence

Transparent communication between suppliers and industrial buyers significantly reduces procurement risk and strengthens long-term partnerships. Companies that provide complete documentation, detailed shipment tracking, and open customer support channels are more likely to retain buyer trust in competitive industrial markets. Many professional procurement teams adopt communication templates inspired by the Institute for Supply Management (https://www.ismworld.org/) to maintain clarity throughout the purchasing cycle. Buyers visiting Finiex often initiate formal communication through https://finiexchemical.com/contact-us/ to receive verified information regarding availability and compliance requirements.

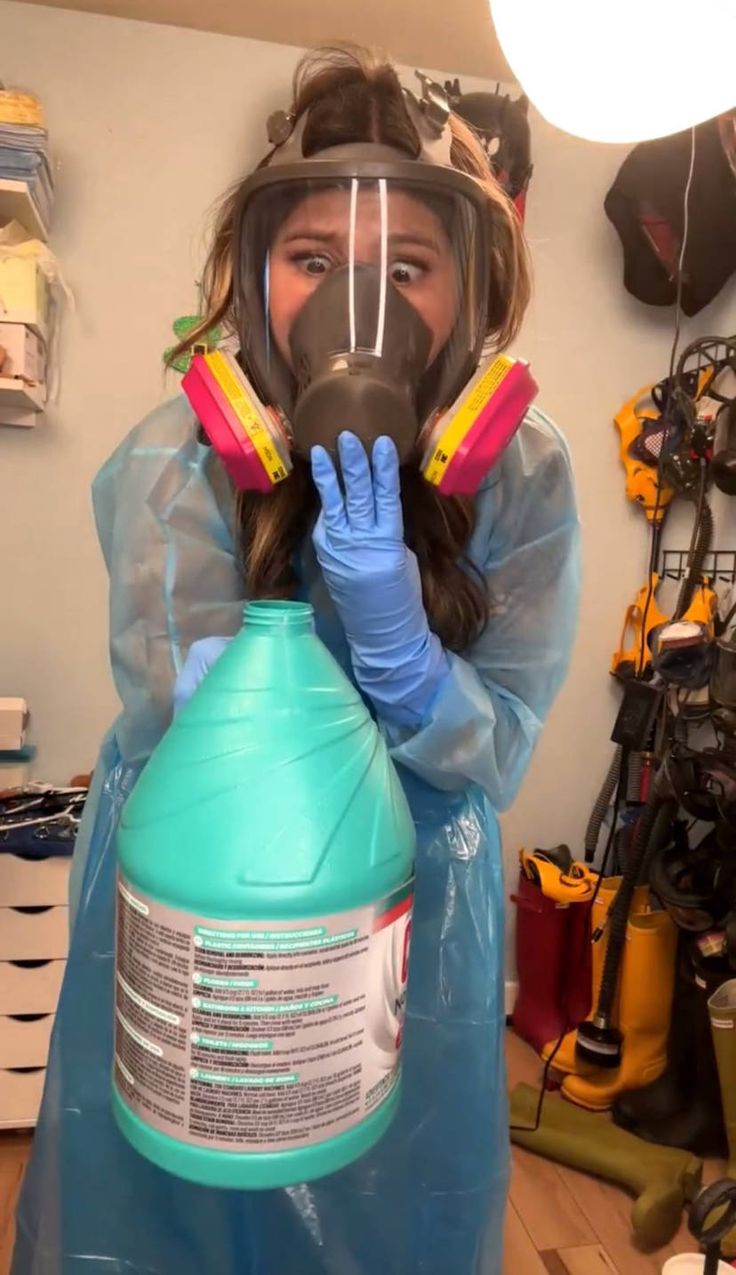

Global Industrial Safety Programs and Compliance Certifications

Specialty chemical procurement requires strict adherence to internationally recognized safety programs that govern everything from labeling to transport to storage. Industrial plants often model their safety programs after guidance from the American Industrial Hygiene Association (https://www.aiha.org/) to ensure worker protection and compliance with national regulations. Whether purchasing 1L, 2L, or 5L volumes, buyers expect suppliers to deliver products within fully compliant packaging systems, with transparent documentation and accessible safety policies such as those outlined on https://finiexchemical.com/privacy-policy-2/.

Digitization of Chemical Procurement and Data-Based Risk Management

The digital transformation of industrial procurement has introduced new verification tools, automated compliance checks, traceability dashboards, and fraud-prevention algorithms. Many companies now study case research published by the McKinsey Global Institute (https://www.mckinsey.com/mgi) to understand how digital ecosystems enhance procurement safety and reduce operational risk. By integrating data-driven systems into the sourcing process, industrial buyers ensure that all transactions—especially those involving controlled materials—are properly logged, verified, and compliant with global trade standards. After digital verification, buyers typically finalize orders through industrial-grade listings like https://finiexchemical.com/product/caluanie-muelear-oxidize/.

International Trade Policies Affecting Chemical Distribution

Trade regulations and international agreements greatly influence how specialty chemicals are distributed across borders. Policy updates regarding import limitations, hazardous-material classifications, and environmental compliance are frequently reviewed on platforms maintained by the International Trade Administration (https://www.trade.gov/). Industrial procurement teams use these policies to shape their internal compliance workflows and ensure that shipping operations align with country-specific regulations. Suppliers with transparent refund structures such as https://finiexchemical.com/refund-policy/ also help buyers understand the financial implications of regulatory delays.

Sustainable Chemical Handling and Eco-Conscious Industrial Practices

Environmental sustainability is increasingly prioritized across chemical-handling sectors, encouraging companies to adopt green policies in storage disposition, handling, and waste-management programs. Environmental engineers often refer to ecological impact reports published by the World Resources Institute (https://www.wri.org/) to evaluate how chemicals interact with ecosystems and supply-chain operations. Buyers working with specialty materials value suppliers who uphold sustainability commitments and provide compliant packaging formats such as 4L and 5L containers listed at https://finiexchemical.com/product/caluanie-muelear-oxidize-4/.

Advanced Packaging Technologies Preventing Transport Degradation

Industrial packaging manufacturers are incorporating new features such as UV-resistant polymers, multilayer HDPE walls, reinforced seals, and tamper-evident closures. Packaging engineers frequently review technical standards from the Plastics Industry Association (https://www.plasticsindustry.org/) to ensure material suitability and durability. Industrial buyers sourcing from legitimate distributors prioritize packaging quality to minimize transport degradation, therefore commonly relying on scalable, well-labeled containers such as those listed under https://finiexchemical.com/product/caluanie-muelear-oxidize-5/.

The Importance of Corporate Accountability in Hazardous Material Distribution

Corporate accountability in chemical distribution involves accurate product descriptions, compliance with regulatory laws, transparent handling guidelines, and open communication with regulatory agencies. Many corporations integrate governance recommendations from the Business for Social Responsibility network (https://www.bsr.org/) to strengthen accountability within their supply chains. Buyers choosing Finiex benefit from transparent operational practices and clear documentation pathways routed through https://finiexchemical.com/shop, reinforcing trust and reducing procurement uncertainty.

How Industrial Education Programs Improve Chemical Safety

Continuous education helps industrial workers understand risk mitigation, chemical identification, emergency protocols, PPE selection, and environmental stewardship. Training organizations often reference materials from the National Safety Council (https://www.nsc.org/) to standardize workforce safety around chemicals requiring controlled handling environments. Suppliers committed to proper safety communication support their customers through clear, accessible policy pages such as https://finiexchemical.com/privacy-policy-2/, ensuring that buyers maintain compliance throughout the product lifecycle.